Intelligent Photovoltaic Cleaning Robot: Technological Innovations and Industrial Applications Based on Todos Products

— Redefining Photovoltaic Operation and Maintenance Efficiency from Deserts to Cities

In the context of global energy transition, the demand for large-scale and intelligent operation and maintenance of photovoltaic power plants has surged. However, traditional manual cleaning methods, with issues of low efficiency, high costs, and significant safety risks, can no longer meet the operational needs of large power plants. The automatic solar panel cleaning robot and remote-controlled solar panel cleaning robot launched by Todos provide revolutionary solutions in the field of photovoltaic cleaning through technological innovation and situational design.

I. Core Product Technical Analysis

1. Fully Automatic Waterless Cleaning Robot

Technical Highlights:

- Breakthrough Cleaning Capability: Utilizing spiral nylon brushes (made of PA610) and high-speed motor drives (60-120 RPM adjustable), achieving a cleaning efficiency of 99% in a single pass, especially effective against high-adhesion pollutants like fine sand in desert areas and industrial dust in cities.

- Intelligent Scheduling System: Remote App control through IoT technology allows for scheduled cleaning (e.g., starting in the early morning during low irradiance periods) and adaptive environmental scheduling (dynamically adjusting frequency based on PM2.5 data).

- Self-Maintenance Design: Automatically executes a high-speed idle brush program after completing tasks to remove residual dust, extending brush life to over three years.

- Extreme Environment Adaptation: Designed with IP65 protection level and a wide temperature range of -30℃ to 70℃, capable of withstanding harsh conditions such as day-night temperature differences in Central Asia’s deserts and coastal salt mist corrosion.

Technical Parameters

| Indicator | Parameter |

|---|---|

| Cleaning Distance | 1600-3000 meters/day |

| Battery Capacity | 24V/16Ah (8 hours of endurance) |

| Obstacle Climbing Ability | ≤22° slope |

| Walking Speed | 12 meters/minute |

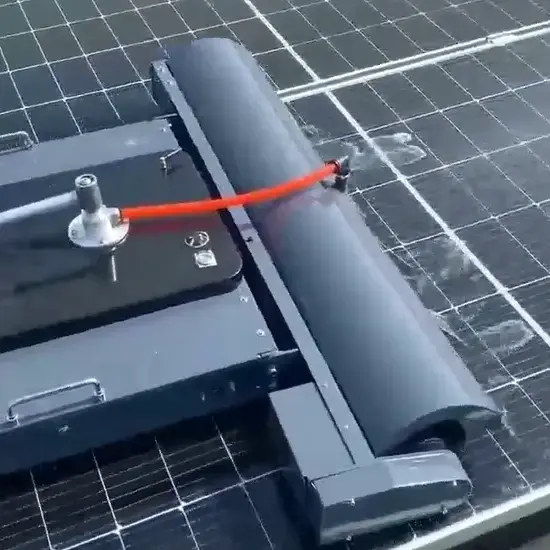

2. Semi-Automatic Water Wash/Dry Cleaning Hybrid Robot

Differentiated Advantages:

- Multi-functional Cleaning Mode: Supports dry sweeping (PA brush) and water washing (optional high-pressure micro-water spray), suitable for agricultural photovoltaics (bird droppings, pollen) and rooftop distributed scenarios.

- Safety Upgrade: Equipped with four ultrasonic sensors and vacuum suction cups to prevent slipping while working on roofs with a 25° incline, reducing the risk of component micro-cracking by 0.5%.

- Lightweight Design: Weighs only 15 kg, adaptable for truck transportation and flexible deployment at small power plants.

Core Functions

- Remote Monitoring: 4G module for real-time transmission of work logs and fault codes (e.g., brush blockage warnings).

- Breakpoint Resumption: Automatically locates uncleaned areas after unexpected power outages and resumes tasks once power is restored.

II. Comparison Advantages over Traditional Cleaning Methods

| Dimension | Todos Robot | Manual Cleaning |

|---|---|---|

| Cleaning Efficiency | 1000 m²/hour (automatic) | 200 m²/hour (3-person team) |

| Power Generation Gain | Annual increase of 10-65% (desert measured) | Temporary increase, 50% decline after 1 week |

| Safety Risks | Zero high-altitude work risks | Annual accident rate of 0.3% (industry data) |

| Water Resource Consumption | Zero (dry sweeping) or 0.5L/m² (water wash) | 1.2L/m² (high-pressure water gun) |

| Full Lifecycle Cost | Higher initial investment, breakeven in 2 years | Annual labor cost increases by 8% |

III. Typical Application Cases

- Desert Centralized Power Station:

- Challenge: Dust storms lead to an average daily accumulation of 5g/m², resulting in over 20% power generation loss.

- Solution: Deploying a cluster of fully automatic robots for cleaning every early morning, combined with self-developed AI algorithms to optimize paths (reducing 30% of repeated coverage).

- Outcome: A 200MW power station in Xinjiang increased annual power generation by 18% and saved 36,000 tons of water.

- Urban Commercial Rooftops:

- Challenge: High roof slope (20°) and irregular component arrangements.

- Solution: Mixed robots equipped with a track extension system for remote path planning to avoid obstacles like ventilation equipment.

- Outcome: A rooftop power station at a car factory in Shanghai reduced operation and maintenance costs by 45% without safety incident records.

IV. Technological Evolution and Industry Impact

The innovation of Todos products marks the entry of photovoltaic cleaning into the “Unmanned 3.0 Era”:

- Data-Driven Operations: Implementing preventative cleaning through dust accumulation models and power generation loss algorithms (e.g., initiating emergency cleaning before dust storm warnings).

- Modular Expansion: Supporting additional modules such as thermal imaging cameras (for hotspot detection) and drone-assisted inspections.

- Carbon Neutral Contribution: Each robot can reduce 54 tons of CO₂ emissions annually (calculated through increased power generation efficiency).

V. Conclusion

Todos’ intelligent cleaning robots not only solve the “last mile” challenges of photovoltaic operation and maintenance but also reconstruct the industry ecosystem through the “Cleaning-as-a-Service” model. As photovoltaic installations exceed the TW-level, such technologies will become standard tools in power station asset management, pushing global renewable energy operations into a new era of higher efficiency and lower carbon emissions.