Robotic Solar Panel Cleaning Systems: Cost Analysis and ROI Evaluation

Product Overview

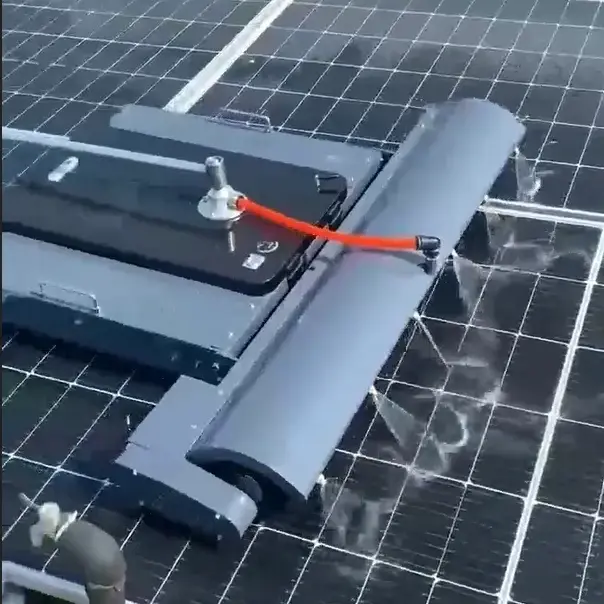

The Automatic Solar Panel Cleaning Machine and Remote Control Solar Panel Cleaning Robot are designed to address the challenges of maintaining solar panel efficiency in large-scale installations, particularly in deserts, urban areas, and high-pollution zones. Below are their key specifications and capabilities:

Key Product Parameters

- Automatic Solar Panel Cleaning Machine

- Cleaning Method: Dry sweep (waterless), with optional wet cleaning customization.

- Cleaning Efficiency: >98% dust removal.

- Daily Operation: Fully automated, once-daily cleaning.

- Technical Data:

- Cleaning distance: 1,600–3,000 meters.

- Battery: 24V/16Ah.

- Brush material: Non-dust flexible PA610.

- Obstacle crossing: ≤22° slope.

- Operating temperature: -30°C to 70°C.

- IP65 protection rating.

- Smart Features:

- Remote control via app or internet.

- Self-cleaning program for brush maintenance.

- Real-time work reports and fault diagnostics.

- Lifetime software upgrades.

- Remote Control Solar Panel Cleaning Robot

https://todos-china.com/solar-panel-washing-robot/ - Cleaning Methods: Dry sweep or water washing.

- Cleaning Efficiency: >98%.

- Operation: Semi-automatic with remote control.

- Technical Data:

- Cleaning speed: 1,000 m²/h.

- Wet washing angle: 0°–15°; dry cleaning angle: 0°–25°.

- Weight: 15 kg (excluding brush).

- Features:

- Breakpoint resume, low-battery auto-return.

- 4G connectivity for real-time monitoring.

Solar panel cleaning systems Cost Analysis

- Manual Cleaning Costs

- Labor: Cleaning a 1 MW solar farm (1,818 panels) costs $1,363.5–$7,272 per session.

- Frequency: Annual cleaning costs over 15 years:

- Once/year: $20,452.5–$109,080.

- Four times/year: $81,810–$654,480.

- Risks: High labor costs, safety hazards (e.g., falls, electric shocks), and potential panel damage.

- Robotic System Costs

- Initial Investment:

- 1 MW farm requires 3 robotic units, costing $10,000–$20,000 (one-time).

- Operational Savings:

- Eliminates labor costs.

- Reduces water usage by 100% (dry cleaning).

- Minimizes panel damage (no manual handling).

- Initial Investment:

Solar panel cleaning system ROI Calculation

- Energy Output Increase:

- Dust reduces panel efficiency by 10–30%. Robotic cleaning restores 10–65% lost generation.

- Example: A 1 MW farm generating $100,000/year could recover $10,000–$65,000 annually in additional revenue.

- Payback Period:

- Scenario: Initial investment = $20,000; annual revenue gain = $30,000.

- Payback: 8–24 months, depending on local dust levels and energy prices.

- Long-Term Savings:

- Over 15 years, robotic systems save $61,810–$634,480 compared to manual cleaning.

- Extended panel lifespan (reduced micro-cracks and corrosion) further lowers replacement costs.

Why Invest in Robotic Systems?

- Efficiency Boost: Maximize energy output with daily cleaning.

- Cost Reduction: Eliminate labor and water expenses.

- Safety & Sustainability: No high-altitude work risks; waterless operation conserves resources.

- Smart Management: Remote monitoring, fault diagnostics, and automated scheduling streamline operations.

Conclusion

Robotic solar panel cleaning systems offer a compelling ROI, with payback periods under two years and long-term savings exceeding manual methods by 3–10x. For large solar farms in arid or polluted regions, these systems are not just cost-effective but essential for maintaining competitiveness and sustainability.

Recommendation: Prioritize deployment in high-dust environments (e.g., deserts) to maximize energy recovery and ROI. Customize wet/dry functions based on local water availability and pollution levels.