In the ever-expanding world of renewable energy, solar farm cleaning robots et machines de nettoyage de fermes de panneaux solaires are revolutionizing the maintenance of photovoltaic (PV) panels. By ensuring optimal performance and longevity of solar panels, these innovations significantly reduce maintenance costs, enhance energy efficiency, and promote sustainability. Let’s dive deep into the key components, functionalities, applications, and benefits of these cutting-edge cleaning systems.

Key Components and Functionalities of Solar Farm Cleaning Robots

1. Advanced Control Systems

The heart of any solar panel farm cleaning machine lies in its control system. Most models utilize sophisticated controllers such as the STM32 microcontroller or ARM chip MKW01Z128, which adeptly manage operations like motor control and sensor input processing.

- PWM Motor Drive Circuit: Essential for precise movement, the core controller sends PWM (Pulse Width Modulation) signals, governing the speed and direction of the motors.

- Remote Control Capabilities: Many solar farm cleaning robots are equipped with internet-based remote control systems, enabling operators to clean from afar, while manual control is available for immediate needs.

2. Intelligent Sensing Systems

Effective cleaning starts with accurate sensing.

- Light Detection Modules: Robots often include light-sensitive resistors (like TELESKY sensors) that trigger cleaning cycles based on ambient light levels, ensuring operations initiate when they’re most effective.

- Boundary Detection Modules: These modules, using limit switches (e.g., Omron D4N-212G), help clean around edges without causing damage.

3. Efficient Drive Systems

The movement systems of solar farm cleaning robots employ reliable motors, typically DC or brushless DC types.

- Reduction Gearbox: This component adjusts motor speed, allowing the robot to clean at an optimal pace.

- Braking Systems: To enhance operational safety, these robots are often equipped with braking systems for quick halts at the end of cleaning cycles or while transitioning between rows.

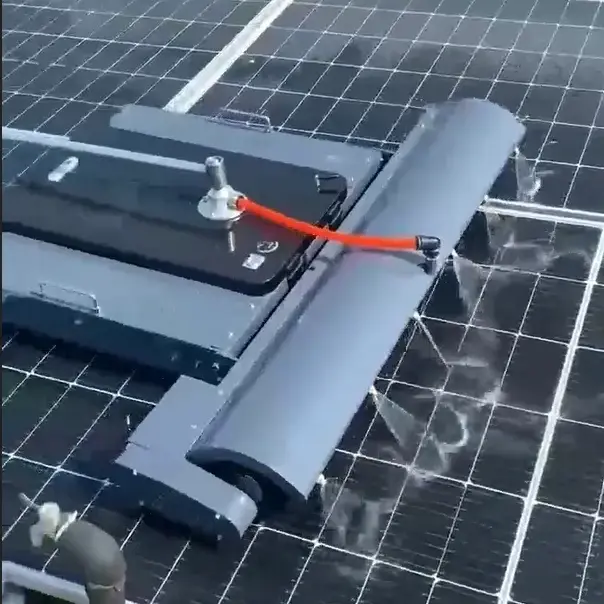

4. Versatile Cleaning Systems

Different scenarios require different approaches, which is why robotic cleaning systems employ various techniques.

- Spray and Blower Mechanisms: For effective cleaning, some robots utilize water or compressed air to remove dirt and dust, supported by rotating brush rollers typically made of nylon.

- Dry Cleaning Options: In water-scarce areas, methods such as negative pressure or brushes facilitate dry cleaning, benefiting regions with limited water availability.

- Mix dry cleaning and water cleaning. A more efficient way to clean.

Application Scenarios

1. Large-Scale Ground Solar Farms

Solar farm cleaning robots are optimized for extensive solar installations.

- Automatic Row Changing: Equipped with track systems, these robots autonomously shift between rows, maximizing cleaning efficiency.

- Carrier Vehicles: Designed for easy transport, these vehicles facilitate the movement of cleaning robots between cleaning zones.

2. Roof Solar Farms

Robots designed for roof solar farms focus on compactness and lightweight features to protect rooftop structures.

- Self-Powered Systems: With integrated solar panels and battery systems, these robots can function without external power sources.

- High Efficiency: Capable of cleaning 200 meters of solar arrays in around 40 minutes, they are indispensable for high-density installations.

Benefits of Solar Panel Farm Cleaning Machines

1. Reduced Labor Costs

Automation plays a pivotal role in lowering labor costs. By reducing reliance on manual cleaning, operators benefit from savings in both time and expenses.

2. Enhanced Cleaning Quality

With consistent performance, solar farm cleaning robots ensure that PV panels are always operating at peak efficiency. Different cleaning modes allow adaptation to various environmental conditions.

3. Resource Conservation

Solar farm cleaning robots significantly minimize water consumption—using only a quarter of the water required for manual methods—making them ideal for water-scarce regions. Their self-power capabilities further promote sustainability efforts.

Challenges and Solutions

Initial Development Costs

We have successfully tackled the challenge of high initial development and deployment costs associated with solar farm cleaning robots. Through strategic planning and innovation, we have made these advanced technologies more accessible, even for larger installations.

Environmental Adaptability

Our solar farm cleaning robots are designed to perform effectively in challenging conditions, such as heavy dust in desert areas and extreme temperatures. We have implemented advanced engineering solutions and selected robust materials to ensure reliable operation under various environmental factors.

Maintenance Needs

We prioritize long-term reliability and optimal performance by incorporating regular servicing and maintenance protocols. Our robots now feature enhanced fault detection and self-repair capabilities, ensuring they remain efficient and effective with minimal downtime.

Conclusion

In conclusion, solar farm cleaning robots et machines de nettoyage de fermes de panneaux solaires are essential tools for advancing solar energy maintenance. By delivering enhanced cleaning quality, significant labor savings, and responsible resource use, these robots contribute to achieving global sustainability goals. As technology continues to evolve, the efficiency, adaptability, and cost-effectiveness of these systems will only improve, paving the way for their widespread adoption across various solar farm environments. Embracing these innovations today sets the stage for a greener tomorrow.